In the tangled industry of cable maintenance where durability and precision are paramount, the utilization of modern tools like wire rope lubricators and cleaners have become essential. These new devices are essential to ensure that cables function smoothly and last longer across various industries. In this article, we delve into the importance of lubricating and lubricating wire ropes as well as wire cleaners in cable maintenance and cable cleaning, examining their roles as well as the benefits and positive impact they can have on the overall efficiency of operations. For more information, click Wire Cleaning

Understanding Wire Rope Lubricants:

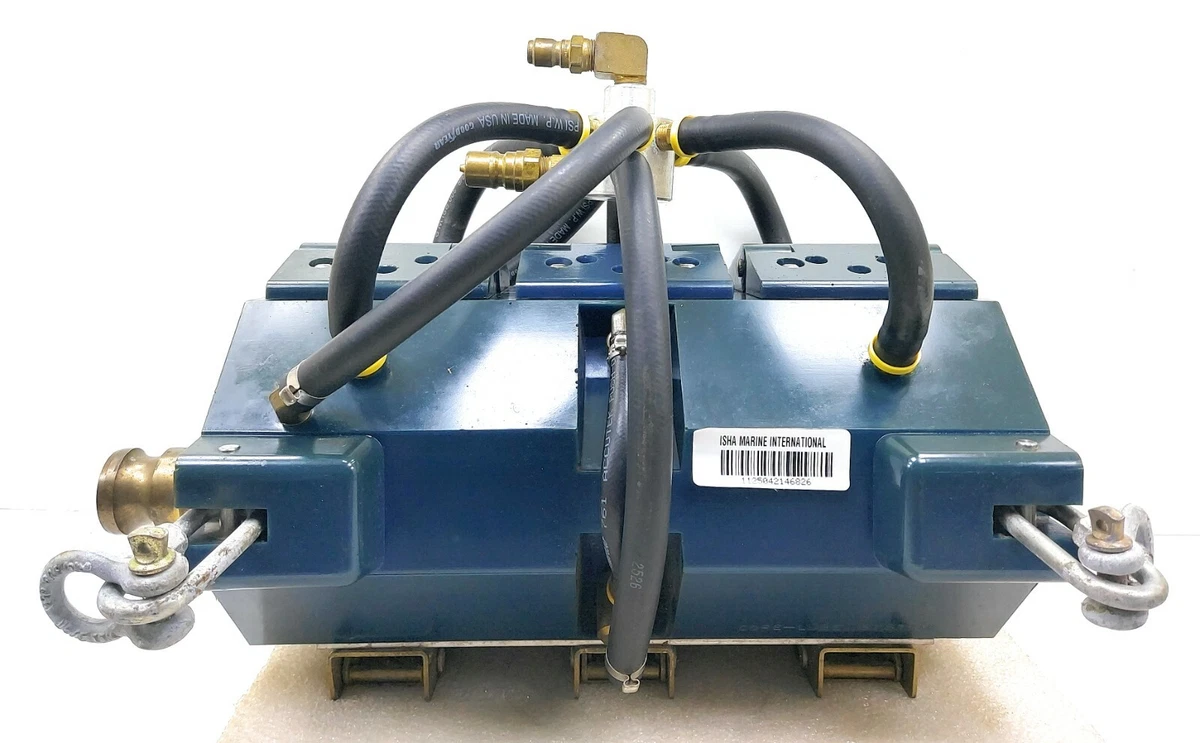

Wire rope lubricators are specialized devices that apply lubrication to wire ropes systematically. This is necessary for preventing rust, reducing friction and improving overall durability. The lubricator ensures that the lubricant agent is evenly distributed along the length of the wire rope. This provides complete protection against wear and tear.

How to maintain cables using wire cleaners:

Wire cleaners, also known as cable cleaners, play a vital role in maintaining the hygienic condition of cables. They are designed for removing contaminants, debris and fluids that could build up on cable when performing various operations. Wire cleaners are necessary in harsh environments, where cables are subjected to extreme conditions. They are designed to ensure maximum performance and avoid damage to the cable.

Optimizing Cable Lifespan:

Combining wire cleaners with wire rope lubricators can increase the cable’s lifespan. Through the systematic application of lubrication using wire rope lubricators, and then removing the contaminants using wire cleaners, cables are shielded from the negative results of corrosion, friction and external elements. This safeguarding of the integrity of the cable translates into prolonged operational efficiency as well as lower maintenance costs in the long run.

Effectiveness in application

Wire rope lubricators were designed to be easy to utilize and efficient in their use. They can be utilized for a variety different sizes and types of wire ropes. This allows for versatility in cable maintenance. The automated and systematic application of lubrication guarantees consistency that eliminates the danger of uneven coverage that manual methods could cause.

Adaptability to Challenging Environments

Wire rope lubricators, and cleaners for wires, are crucial in industries where cables face harsh conditions, like the ones used in drilling, construction or maritime activities. They are made to endure harsh conditions and offer reliable cable maintenance tools in a range of configurations.

Cost-Effective maintenance solutions:

In the long term, using wire cleaners and lubricators for wires to maintain cables is an effective approach. These modern tools cost a tiny amount relative to the cost of repair, replacement, and downtime that can result from ignoring maintenance.

Conclusion:

Lubricators and wire cleaners for cables are the guardians who ensure cable integrity and accuracy across a broad range of industries. Cleaning up pollutants and the application of lubricants aids in the preservation and longevity of cables. This reduces maintenance and increases operational efficiency. In a field that depends on cables for critical processes, investing in advanced cables maintenance tools like wire rope lubricators, or wire cleaners is not only a smart choice, but also a necessity.